What is a chiller?

Chiller definition

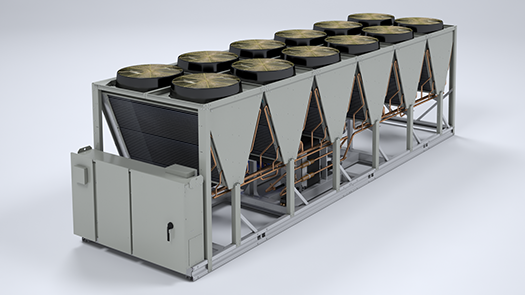

In general, chiller refers to a device that is used to prepare cool water in the Heating, Ventilating and Air Conditioning (HVAC) industry.

Full training of chiller and its types

Chillers are water cooling units that are used in commercial and industrial applications. In the first case, these devices are used independently or in combination with other units such as air conditioners. In this way, the appropriate temperature will be obtained in the space inside the buildings. In the second case, they ensure stable temperature control for industrial processes.

Types of chillers

Based on condenser type

According to the type of condenser used, chillers can be divided into two categories:

- Chillers of “cool air” air cooled chiller

- Chillers of ” cool water ” water cooled chiller

Types based on compressor type

For example, rotary compressors can be used for low capacities (up to 50 kW).Scroll compressors can also be used for medium capacities (up to 80 kW). Screw and centrifugal compressors are also commonly used for higher capacities (500 kW).

CAREL can provide

- The best solutions with high efficiency for all chiller configurations

- Using BLDC technology for rotary or scroll compressors

- Step or stepless control for screw compressors

- Electronic expansion valves EXV

provide that while providing system control that optimizes system performance.

Using the CAREL chiller controller:

- Complete control of the envelope for the main compressor suppliers in the HVAC market, which means complete freedom of choice.

- An integrated solution to ensure the highest efficiency and energy savings, through the combined control of the electronic expansion valve, the compressor and the evaporator and condenser pressure set poin.

- The ability to connect to the most common BMS systems available in the market (BACnet, LonWorks, Modbus, …) and remote monitoring system CAREL tERA.

- Integrate with chillBooster CAREL adiabatic cooling for higher energy efficiency and better unit performance in summer.

- Dual PID control (at chiller startup and steady operation) for more accurate unit management.

- Antifreeze operation based on the saturated refrigerant temperature and not the outlet water temperature, for more effective and faster identification of the risk of freezing inside the evaporator.

Kara Ravesh Saba company has introduced a wide range of its products in the field of air conditioning and refrigeration equipment controllers in the products section of its website.

You can refer to the following addresses to learn about these products and any type of these kits depending on your needs:

In the last part of the text, you can refer to the chiller controller link of Carel Italy for more information.

Leave a Reply