Compression chiller control kit

Chiller controller

The chiller controller is a pre-programmed microprocessor-based system that controls the temperature of chiller through the refrigeration cycle. In this company, the chiller controller is designed to control the compression chiller and is provided to respected manufacturers.

What is a compression chiller?

The chillers in which the high pressure required for the refrigeration cycle is supplied by the compressor are called compression chillers.

What is an absorption chiller?

the required high pressure is provided by heat and a pump, is known as an absorption chiller. The reason for the name absorption for this cycle is the need to absorb the refrigerant in the absorbent liquid to use the pump to increase the pressure.

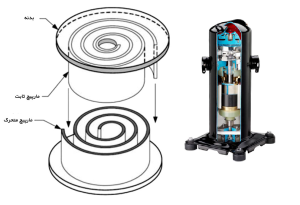

Introducing a sample of compressors

The figure below shows the image of a reciprocating compressor and a scroll compressor. Reciprocating compressors use a cylinder and piston mechanism to increase the pressure of the refrigerant gas, while in scroll compressors, a special mechanism increases the pressure through the twisting of the rotating spiral.

An example of a reciprocating compressor

Example of a scroll compressor

Low-capacity chillers, mini chillers/micro chillers

In many residential or commercial projects, we need chillers that are economical and easy to operate. For example, a 6-story residential building in Tehran requires a chiller with a capacity of 20 tons of refrigeration. Such a load can be achieved with reciprocating or scroll compressors, and two circuits can be used to manage partial loads. It is even better to have the ability to use two compressors in each circuit to optimize energy consumption in partial loads.

Types of compression chiller controllers

Mini chiller controller

In many commercial (or residential) projects, we need an average cooling load of up to 130 tons of refrigeration, and due to the high cooling load of the chiller, we expect more options from the chiller controller. For example, compressor working area control (envelope control), weekly programming capability, free cooling capability, etc. are among these options. In the library of such a controller, the working range of widely used scroll compressor brands in air conditioning should be available.

Considering the increase in refrigeration capacity in these chillers, it is reasonable to expect an increase in the number of load change stages. The use of tandem and trio capabilities in compressors is also one of the features of scroll compressors that should be considered for such chillers. Connecting to the building’s BMS network is considered a necessity for chillers with a medium capacity, and the controller of chillers in this type of the chiller should have the ability to connect via various communication protocols.

For more information about this type of controller, refer to the following link of the products of Kara Ravesh Saba:

Reciprocating chiller controller

Due to the limitation of the refrigerating capacity according to the technology of piston compressors and the limitation of the controller in the previous decades, screw compressors were considered and in fact, the use of reciprocating compressors in the air conditioning industry was limited. But today, due to the development of technology in the field of controllers, piston compressors with a high number of unloaders can be used in medium to high loads and so use the advantages of piston compressors such as low price and ease of repair. Also, with 4 unloaders for each piston compressor, high efficiency can be achieved in medium loads.

For more information about this type of controller, refer to the following link of the products of Kara Ravesh Saba:

Modular chiller controller

Suppose we want to use a chiller in a hotel to provide cooling. The required capacity of the hotel depends entirely on the number of guest rooms and therefore varies greatly throughout the year. The modular chiller was created to meet the needs of such applications so that a large number of chillers can be connected and the final capacity can be increased. In this way, a lot of energy consumption is saved. Obviously, in this system, the cooling water must pass through the evaporator of each module, so in this system, special connections are considered to connect the hydronic system. For more information about this type of controller, refer to the following link of the products of Kara Ravesh Saba:

Screw chiller controller

Screw chillers are the best option for supplying high refrigeration loads. The structure of screw compressors is such that it provides the possibility of three stages of capacity change in the form of 50, 75, and 100%. Also, these compressors can continuously change the load from 50% to 100%. Since screw compressors are produced in high capacities, optimizing their energy consumption is particularly important. Therefore, their controller should have the ability to use electronic expansion valves, free cooling, the ability to use variable speed condenser fans, and inverter compressors Also, due to the very high price of screw compressors, its chiller controller must be equipped with an envelope control system and perform freezing protection and complete control of all chiller protection systems through manual or automatic reset alarms. This system should also be equipped with cold test options to check all its outputs before leaving the chiller factory.

For more information about this type of controller, refer to the following link of the products of Kara Ravesh Saba:

Showing all 5 results