Description

v.VentScrew Series Screw Packaged Controller

The controller of the screw packaged professionally controls both the AHU and condensing units. As you know, when high cooling capacity is required, the use of screw compressors is the main choice. In response to the control needs of packaged and rooftops equipped with screw compressors, the v.VentScrew solution has been made available to manufacturers. Redundancy is one of its other features.

Ventilation: With a fixed structure, it includes supply and exhaust fans, a heating coil, two filter stages, mixed dampers, fresh air dampers, exhaust dampers, and gas dampers.

Condensing unit: in the form of one circuit or two circuits, including one compressor in each circuit and three groups of condenser fans in each circuit.

It has the ability to activate redundancy between two rooftop units in industrial applications.

Screw package controller structure

This company has designed the mentioned solution based on the successful modification of the screw chiller controller program to include air conditioner parameters. Additional parameters can be applied by adding a PLC of cpcoe type to the two-circuit screw solution hardware (Pco5+ X-Large).

It includes air conditioning parameters including supply and exhaust fans, filters, etc. The heating of v.VentScrew series screw package can be provided through a hot water coil, steam coil, electric heater, and heat pump.

Its cooling is also provided through the DX coil.

Common features of screw chiller controller and screw packaged

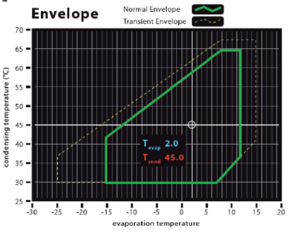

Compressor envelope control

The screw compressor is the most important and expensive part of the device. For this reason, it is very important that its protection should be fully guaranteed.

Compressor envelope control

CAREL’s solution, whether for screw chillers or screw packaged, is the hassle-free management of major compressors in the air conditioning market such as Bitzer, Frascold, Refcomp, Hambell and Fusheng.

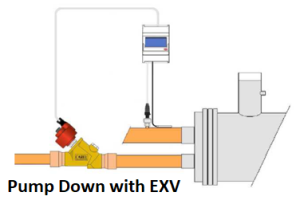

Pump down with EXV

Pump down is a function to protect the compressor during the start. This function turns on the compressor by closing the EXV or liquid line solenoid valve or both until the liquid in the evaporator is completely drained. In this way, there will be no risk of the evaporator liquid being sucked into the compressor at the next start.

Pump Don with EXV

It is recommended to pump down only with the EXV expansion valve because the solenoid valve causes water hammer due to its sudden operation. While the EXV closes gradually and therefore prevents the occurrence of water hammer.

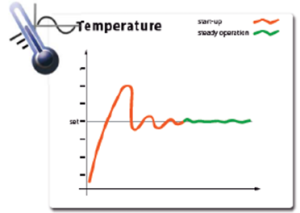

Two PID controls at start and during operation

In the screw packaged, like the screw chiller, the system does not have any estimate of the load demand at the beginning. Therefore, an initial PID control is first used to determine the load estimate. After a few minutes, control will be handed over to the operational PID.

Two PID controls at the start and during the operation

For more information, refer to the following link:

https://www.carel.com/application/roof-top

Leave a Reply