Description

v.VentScroll series scroll packaged controller kit

Scroll packaged controller

Scroll packaged controller of v.VentScroll series is the best option for packaged and rooftops based on scroll compressors on/off. Vida brand uses a user-friendly and modular program to launch the scroll package. This program is a complete collection of operational functions that provides all the hardware facilities needed. All of these hardware and software features are in the form of a kit. The features of this software program cover all the needs of a scroll packaged. This coverage includes a scroll package with small to medium scale, along with the required additional features.

VIDA Scroll packaged controller, which is provided with sensors and peripherals.

Scroll Vida controller packaged, which is provided along with sensors and accessories.

CAREL’s solution for ROOFTOP applications has programmable controls whose inputs and outputs increase based on the complexity of the device. This is a flexible and reliable solution that meets a wide range of needs. The Vida solution has a complete set of peripherals such as displays, sensors, and selectable communication modules.

Types of controller scroll packaged

This product is available in two basic and advanced models. It also provides the possibility to choose the best and most economical option according to the number of compressors.

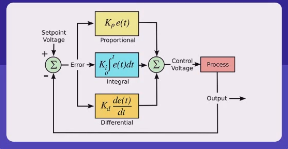

An important point in choosing a scroll-packaged controller is that the fan control settings can be selected. This means that the number of ON/OFF steps of each fan group can be selected up to three steps. Also, in this solution, the type of fan control can be set as ON/OFF or modulating (for example with 0 to 10 VDC output). It can be specified that each of the fan groups comes into the circuit step by step at a certain pressure of refrigerant which is read by the condenser pressure sensor. Other functions such as Set Point can also be specified and adjusted arbitrarily by a PID control loop for each circuit.

Using a PID control loop

A PID control loop can be selected to control and adjust the superheat in the evaporator for each circuit. For this purpose, an electronic expansion valve driver is selected for each circuit along with an expansion valve with a suitable size (based on the design). Which can independently control the superheat temperature.

The design of the superheat temperature control equipment in the v.VentScroll scroll packaged controller is such that with the lowest energy loss, it can quickly reach the superheat temperature to the set point. This control equipment is competitive in every respect compared to other similar systems in the market. The advanced technology of CAREL control valves makes this operation to be done with high speed and accuracy. One of the important control functions that can be activated or deactivated is the rotation management of compressors. These functions can be selected and activated as FIFO and LIFO options in the program for the user.

Using the PID control loop in the v.VentScroll scroll packaged controller kit

The Air Conditioner section of the packaged Unit

In the airconditioner part opackaged, it is possible to control a simple Full Fresh air conditioner to a complete air conditioner with a supply + return fan. It comes with all types of energy recovery systems and there are both basic and advanced solutions.

In the v.VentScroll scroll packaged controller, the choice of fan control type with CAV, VAV, and ON/OFF strategy can be selected according to customer needs and as an option. Even in the future, based on the user’s needs, if there is enough I/O (Input/output) in the hardware (it is possible to add two expansion cards to increase I/O), the type of control strategy of different systems can be changed. It means that the features can be expanded or reduced, and adding or removing any feature does not require correcting the software.

It is possible to manage and control the dampers as ON/OFF and modulating according to the control strategy of the air conditioner. If the Free Cooling function is activated, the motor control of the dampers will be selected intelligently and gradually.

Monitoring Functions:

In the monitoring section of filters for aluminum, bag, and HEPA (for hygienic systems) it is possible to control, monitor, and operate them. This control is based on DPT and DPS sensors. The operating hours of fans, valves, compressors, and dampers are continuously calculated and monitored by the control system.

At the specified time specified by the user, an alarm can be set for periodic service of this equipment based on the operating hours. To announce the need for service as a warning in due time. Before starting up, all active equipment such as fans, valves, and compressors can be activated or deactivated for manual testing (cold test).

Facilities of the monitoring:

The facilities in the monitoring and supervision section can be used by default, Mod boss RTU, and TCP/IP protocols. Therefore, to use this equipment in the building management system (BMS), the addresses of the Mod boss can be controlled in advance and easily.

Among the wide range of features offered by the Vida brand is a monitoring system. Which can be used Plug and Play. The scroll curl packaged controller makes the operators of such systems unnecessary to create expensive monitoring systems.

The V.BOSS and V.CLOUD systems allow the creation of a local monitoring structure or a remote connection quickly. This is even though the possibility can be provided without the need to create a costly monitoring infrastructure. These systems can identify the information and performance of air conditioning systems and other sub-systems of the VIDA brand without the need for any programming and collect and store performance information.

The user can view the performance report of these systems (trend) in the form of graphic and image charts with report management capabilities and high visual quality. They also use data analysis (after Data Acquisition) to optimize systems at the installation site or in the test room.

Also, similar facilities have been designed in a cloud space for the supervision and monitoring of equipment called V.CLOUD, which by using the Internet of Things technology and the membership of users in this system, they will be able to access the managed systems remotely. In this way, it provides them with a wide range of services including optimization, setup, monitoring, and control.

User interfac

In the CAREL scroll packaged controller, various user interfaces such as a display (PGDE) and color HMI (Human Machine Interface) are available with different dimensions (4.3, 7, 10 inches). The PGDE display, which has six simple control keys, is usually used to make settings quickly. This equipment is very useful when setting up and adjusting various ventilation and refrigeration systems.

Another very powerful feature of this solution is the web user interface. These features are loaded by default in the controller associated with these solutions. The user will have access to these web pages through the TP/IP protocol, which provides extensive facilities to the user.

Rooftop controller kit

The CAREL rooftop controller kit for small to medium-capacity scroll roof tops includes a control unit as well as the PGDE operator terminal and sensors to control a two-circuit device equipped with two scroll compressors and a condenser fan in each circuit.

To get information about the controller of this kit, you can refer to the CAREL website at the following address:

Leave a Reply